ISO 9001:2015 Certified Company

Follow Us On :

Support : +91-20-25293212

Email : info@ktkindia.com

Home » Products

Drilling Machines - Hydraulic Feed

1st Generation - Sutaible for production of 30000 to 50000 components per month.

Features under this category

- Hydraulically Operated Economical Machines.

- Low cost automation.

- Rigid construction.

- Drilling cycle (Rapid forward - feed - dwell - Rapid return).

- Spindle drive through stepped pulley.

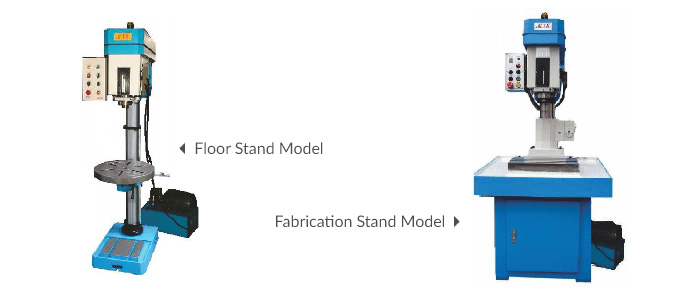

- Machines also available in fabricated stand models.

- Machines can be equiped with multi spindle heads for mass production.

| Hydraulic Standard Drilling Machines | ||

| Model | H-2500 | H-2000 |

| Max. Drilling Capacity | Ø 25mm | Ø 19mm |

| Spindle Taper | MT3 | MT3 |

| Spindle Travel | 130mm | 100mm |

| Number of Speed | 4 | 3 |

| Spindle Speed (Optional) | 500-1180 rpm 1380-1910 rpm |

500-1180-1900 rpm |

| Column Diameter | Ø 102mm | Ø 92mm |

| Table Size | 600*400mm | 500*400mm |

| Max Distance from (spindle to table) | 100-630mm | 100-400mm |

| Max Dist. from (spindle to table) | 930mm | 600mm |

| Motor HP | 2HP | 1.5HP |

| Hydraulic Power | 20 kg/sq.cm | 20 kg/sq.cm |

| Overall Height | 2100mm | 2000mm |

| Weight | 600kg | 450kg |

Standard Accessories

- Complete Hydraulic systems duly interface with the mother machine.

- Main motor of reputed brand, duly assembled with all drive elements.

- Comprehensive electrical control panels and operting pendant duly wired to the basic machine.

- Intermediate Table with Rack & Pinion arrangement for lifting and lowering of Work Table.

- Operation and maintenance manual.

Optional Accessories

- Tool holders suitable for application.

- Coolant system consisting of:- Reservoir tank with chip collection tray, separation baffles, electric coolant motor, flexible piping & fittings, on/off valves, splash guards etc.

- Flexible lighting arrangement.

- Square work table

- Jigs & Fixtures.