ISO 9001:2015 Certified Company

Follow Us On :

Support : +91-20-25293212

Email : info@ktkindia.com

Home » Products

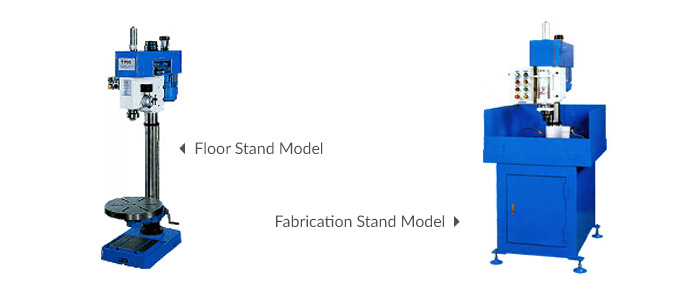

Tapping Machines - Lead Screw Type

2nd Generation - Sutaible for production of 20-25 pcs components per minute.

Features under this category

- Tapping cycle (Tap forward cycle - dwell - Tap reverse cycle)

- Spindle drive through step/timer pulley.

- Inbuilt job counter & tool change counters.

- Inbuilt clamp / de-clamp cycle for tooling automation.

- 3 Phase, 50Hz, TEFC, F class insulation, Induction Motor with temperature sensors with its controller.

- Automatic tapping is driven by Lead Screw which provides standard pitch, accurate thread and consistent quality level for tapping.

- Easy replacement of Lead Screw for different pitches, fitted externally.

- There is no reverse cut or pulling force on component during return stroke of tapping.

- Machines can be equipped with Multi-Spindle Heads for mass production.

- Machines available in Horizontal as well as Vertical axis.

| Lead Screw Automatic Tapping Machine | |||

| Model | T140 | T120 | T100 |

| Maximum Tapping Capacity (S45C) | M30 | M20 | M10 |

| Spindle Taper | MT4 | MT3 | JT6 |

| Spindle Travel | 140mm | 120mm | 100mm |

| Spindle Speeds (Optional) | 100-800rpm | 100-1000rpm | 500-830-1250rpm |

| Throat (Column to Spindle Centre) | 260mm | 230mm | 180mm |

| Table Area | 600*400mm | 500*400mm | 400*300mm |

| Column Diameter | Ø 115mm | Ø 102mm | Ø 80mm |

| Distance from Spindle To Table | 100-700mm | 100-600mm | 100-400mm |

| Motor HP (6P) | 3HP | 2HP | 1HP |

| Overall Height | 2100mm | 2100mm | 1600mm |

| Weight (Approx) | 700kg | 600kg | 220kg |

Standard Accessories

- Operation and maintenance manual.

- Spindle motor of reputed brand, 3 Phase, 50 Hz, TEFC, F Class insulation, duly assembled with all drive elements.

- Comprehensive electrical control panels without protection device.

- Flexible lighting arrangement.

Optional Accessories

- Tool holders suitable for application.

- Variable frequency Drive for main spindle infinite speed variation.

- Coolant system-complete with necessary splash guards etc.

- Component orientation & clamping fixture as per application.

- Machine cladding.

- Centralized lubrication system if required.

- Inbuilt job counter and tool change interlock facility